How Robotics is Enhancing Mining Safety

In the ever-evolving landscape of the mining industry, robotics stands out as a game changer, revolutionizing the way we approach safety and efficiency. Imagine a world where workers are no longer exposed to the perils of hazardous environments, where technology takes the helm in dangerous situations, and where productivity soars without compromising human safety. That's the promise of robotics in mining! As we delve deeper into this transformative technology, we will uncover how robotics is not just a futuristic concept but a practical solution that is already making waves in the industry.

Robotics has seamlessly integrated into mining operations, enhancing not only the safety of workers but also the overall efficiency of operations. The introduction of robotic systems has paved the way for innovative solutions that tackle some of the most pressing challenges faced by the mining sector. From autonomous vehicles that transport materials to drones that conduct aerial surveys, the application of robotics is vast and varied. But what does this mean for the average miner? It means fewer accidents, reduced exposure to hazardous conditions, and ultimately, a safer working environment.

As we explore the various types of mining robots, it becomes clear that each has its unique role in enhancing safety. For instance, autonomous vehicles are designed to navigate the rugged terrains of mines, transporting materials without the need for human intervention. This not only minimizes the risk of accidents but also allows human workers to focus on more complex tasks. Similarly, drones have emerged as invaluable tools for surveying and monitoring, providing real-time data that helps in making informed decisions quickly. The integration of these technologies is not just about replacing human labor; it's about augmenting human capabilities and ensuring that safety is always the top priority.

As we look ahead, the future of robotics in mining safety appears bright. With continuous advancements in technology, we can expect to see even more innovative solutions that enhance safety standards. The potential for robotics to transform the mining industry is immense, and as we embrace these changes, we must also consider the challenges that come with them. However, the benefits far outweigh the hurdles, and the commitment to safety will undoubtedly drive further innovations in this field.

- How do autonomous vehicles improve mining safety?

Autonomous vehicles reduce human exposure to hazardous conditions by performing transportation tasks without the need for human drivers, thereby minimizing accidents. - What role do drones play in mining safety?

Drones are used for surveying and monitoring, allowing for real-time assessments of mining sites, which enhances safety and operational efficiency. - Are there any challenges in implementing robotics in mining?

Yes, challenges include technical limitations, the need for regulatory compliance, and the integration of new technologies into existing operations. - What is the future of robotics in mining?

The future promises further advancements in safety technologies, with innovations that will continue to improve safety standards in the mining industry.

Introduction to Robotics in Mining

Robotics has revolutionized numerous industries, but its impact on mining is particularly noteworthy. Imagine a world where heavy machinery operates autonomously, reducing the risk of accidents and enhancing efficiency. This is not science fiction; it's the reality of modern mining operations. The integration of robotics into mining is akin to adding a safety net to a high-wire act—providing both security and precision in an inherently dangerous environment.

In the mining sector, the adoption of robotics has been driven by the need for improved safety measures and operational efficiency. Traditional mining practices often expose workers to hazardous conditions, such as unstable ground, toxic gases, and heavy machinery accidents. By implementing robotic technologies, mining companies can significantly reduce human exposure to these dangers. For instance, autonomous vehicles are now used to transport materials in mines, allowing human workers to focus on tasks that require their expertise while minimizing their risk.

Moreover, the potential of robotics in mining extends beyond mere transportation. Drones, equipped with advanced sensors and cameras, are employed for surveying vast mining sites, providing real-time data that enhances decision-making processes. These drones can access areas that are difficult or dangerous for humans to reach, ensuring thorough inspections and monitoring without putting lives at risk.

As we delve deeper into the various types of mining robots, it becomes clear that the technology is not just about replacing human labor; it's about augmenting it. The synergy between human intuition and robotic precision creates a safer, more efficient mining environment. With robotics, mining companies are not only enhancing productivity but also setting new standards for safety that could redefine the industry.

Types of Mining Robots

When we think about the mining industry, the first images that often come to mind are of rugged terrain, heavy machinery, and, unfortunately, dangerous working conditions. However, the advent of robotics has revolutionized the way mining operations are conducted, significantly enhancing both safety and efficiency. In this section, we will delve into the various types of mining robots that are currently transforming the industry. From autonomous vehicles to drones, each of these technologies plays a pivotal role in making mining safer and more productive.

One of the most remarkable innovations in mining robotics is the development of autonomous vehicles. These vehicles are designed to operate without human intervention, navigating the complex and often hazardous environments of mines. By transporting materials and conducting routine operations, they minimize the exposure of human workers to dangerous conditions. Imagine a scenario where a vehicle can autonomously traverse a mine, avoiding obstacles and hazards, all while carrying heavy loads. This not only improves safety but also boosts efficiency as operations can continue around the clock without the fatigue that human workers may experience.

Another exciting advancement in mining robotics is the use of drones. These flying robots are increasingly utilized for a variety of tasks, such as surveying, monitoring, and inspection. Drones can quickly cover large areas, providing real-time data that is invaluable for planning and operational management. For example, a drone equipped with high-resolution cameras can capture detailed images of a mining site, allowing engineers to assess conditions without risking human lives. The ability to gather data from difficult-to-reach areas enhances safety and operational efficiency, proving that drones are not just a novelty but a crucial tool in modern mining.

Moreover, there are specialized robots designed specifically for hazardous environments. These robots are engineered to perform tasks in conditions that would be perilous for human workers. For instance, robots can be deployed to conduct inspections in areas with toxic gases or unstable ground. By utilizing these machines, mining companies can ensure that human workers are kept out of harm's way while still maintaining operational standards. The integration of robotics in these scenarios is not just a trend; it is becoming a fundamental aspect of safe mining practices.

In summary, the types of mining robots, including autonomous vehicles and drones, are reshaping the landscape of the mining industry. Their ability to operate in hazardous conditions, combined with their efficiency and safety benefits, makes them indispensable tools for modern mining operations. As technology continues to advance, we can expect even more innovative robotic solutions to emerge, further enhancing safety in this critical sector.

Autonomous Vehicles

Autonomous vehicles are revolutionizing the mining industry by providing a safe and efficient means of transporting materials and personnel. Imagine a massive truck, fully equipped with sensors and AI, navigating through rugged terrains without a human driver. This is not science fiction; it's the reality of modern mining operations. These vehicles are designed to operate in hazardous environments, significantly reducing the risk of accidents that can occur when human operators are involved.

One of the most impressive aspects of autonomous vehicles is their ability to operate continuously, allowing for increased productivity. They can work around the clock, transporting ore and waste from mining sites to processing facilities without the need for breaks. This not only accelerates the mining process but also maximizes the output of resources. Furthermore, the integration of advanced technologies such as GPS and real-time data analytics allows these vehicles to navigate complex mining sites efficiently, avoiding obstacles and adapting to changing conditions.

In terms of safety, autonomous vehicles offer a multitude of benefits:

- Reduced Human Exposure: By taking over dangerous tasks, these vehicles minimize the number of workers exposed to hazardous environments.

- Enhanced Precision: Equipped with advanced sensors and cameras, autonomous vehicles can execute tasks with remarkable accuracy, reducing the likelihood of errors that could lead to accidents.

- Predictive Maintenance: These vehicles can monitor their own performance and alert operators to potential issues before they become serious problems, thus preventing breakdowns that could jeopardize safety.

Moreover, the design of these vehicles is tailored specifically for the mining environment. They are built to withstand extreme conditions, including rough terrain, dust, and moisture. This durability not only extends the lifespan of the vehicles but also ensures that they can operate effectively in the challenging conditions often found in mining operations.

However, the journey to fully autonomous mining is not without its challenges. Technical limitations, such as the need for robust communication networks in remote areas, pose significant hurdles. Additionally, regulatory compliance and safety standards must evolve to accommodate these new technologies. The industry must work collaboratively to address these challenges, ensuring that the implementation of autonomous vehicles enhances safety without compromising operational integrity.

In conclusion, autonomous vehicles represent a significant leap forward in mining safety and efficiency. By reducing human exposure to dangerous tasks and increasing operational productivity, they are paving the way for a safer, more efficient future in the mining industry. As technology continues to advance, we can expect to see even more innovative solutions that will further enhance the safety and effectiveness of mining operations.

Benefits of Autonomous Vehicles

Autonomous vehicles are revolutionizing the mining industry in ways that were once thought to be the stuff of science fiction. These high-tech machines are not just fancy gadgets; they are critical tools that enhance safety, improve efficiency, and significantly reduce operational costs. Imagine a world where heavy machinery operates without the risk of human error—this is the reality that autonomous vehicles bring to mining operations.

One of the most significant benefits of using autonomous vehicles is the enhanced safety they provide. By taking over the most dangerous tasks, these vehicles minimize human exposure to hazardous conditions. For instance, when transporting materials through treacherous terrains or during adverse weather conditions, autonomous vehicles can operate without putting human lives at risk. This is particularly vital in mining, where risks such as cave-ins, equipment failures, and toxic gas emissions are prevalent.

Moreover, the use of autonomous vehicles leads to increased productivity. These machines can operate around the clock without the need for breaks, sleep, or shift changes. This continuous operation not only maximizes output but also allows for more efficient use of resources. When you think about it, it’s like having a tireless worker who never complains and always gets the job done. This level of efficiency can significantly impact the bottom line, making mining operations more profitable.

Another noteworthy advantage is the reduction in operational costs. Although the initial investment in autonomous technology may be high, the long-term savings are substantial. With fewer accidents, reduced downtime, and lower insurance costs, companies can see a significant return on investment. Additionally, the operational efficiency gained through automation can lead to lower labor costs, as fewer workers are needed to manage the same amount of work.

To summarize, the integration of autonomous vehicles into mining operations offers a multitude of benefits, including:

- Improved safety by reducing human exposure to dangerous conditions.

- Increased productivity through continuous operation without breaks.

- Reduced operational costs due to fewer accidents and lower labor needs.

In conclusion, as the mining industry continues to evolve, the adoption of autonomous vehicles stands out as a game-changer. These vehicles not only enhance safety but also pave the way for a more efficient and profitable mining sector. As technology advances, we can only expect these benefits to grow, making mining a safer and more sustainable industry for the future.

Q1: How do autonomous vehicles improve safety in mining?

A1: Autonomous vehicles reduce human exposure to hazardous conditions by performing dangerous tasks, thereby minimizing the risk of accidents and injuries.

Q2: Are autonomous vehicles cost-effective for mining companies?

A2: Yes, while the initial investment may be high, autonomous vehicles lead to long-term savings through improved efficiency, reduced labor costs, and lower accident-related expenses.

Q3: Can autonomous vehicles operate in all mining conditions?

A3: While autonomous vehicles are designed to handle various conditions, their effectiveness can vary based on terrain and environmental factors. Continuous advancements in technology are improving their capabilities.

Challenges of Implementing Autonomous Vehicles

Implementing autonomous vehicles in the mining industry is not without its hurdles. While the benefits are clear and compelling, the road to full adoption is fraught with challenges that need careful navigation. One of the primary issues is the technical limitations of current technology. Autonomous vehicles rely heavily on advanced sensors, artificial intelligence, and real-time data processing to operate safely and efficiently. However, in the unpredictable and often rugged terrain of mining sites, these technologies can struggle to perform optimally. For instance, adverse weather conditions like heavy rain or snow can obscure sensors, leading to potential operational failures.

Moreover, the integration of autonomous vehicles into existing mining operations often requires significant infrastructure upgrades. This means that companies must invest not only in the vehicles themselves but also in the necessary technology to support them. Upgrading infrastructure can be a daunting task, especially for smaller mining operations that may not have the financial resources to make such investments. Additionally, the complexity of integrating these vehicles with human-operated machinery adds another layer of challenge, as safety protocols and operational procedures must be re-evaluated and modified.

Another significant challenge is regulatory compliance. The mining industry is heavily regulated, and introducing autonomous vehicles into the mix raises questions about liability and safety standards. Regulatory bodies may require extensive testing and certification before these vehicles can be deployed, which can delay their implementation. Companies must also navigate the legal implications of accidents involving autonomous vehicles, which can complicate insurance and liability issues. This uncertainty can deter companies from fully committing to the technology.

Finally, there is the human factor to consider. Workers may be apprehensive about the introduction of autonomous vehicles, fearing job displacement or changes to their work environment. This resistance can manifest in various ways, from reluctance to embrace new technologies to outright opposition against their use. Therefore, it is crucial for mining companies to engage with their workforce, providing education and training on how these vehicles will enhance safety and efficiency rather than replace human jobs.

In summary, while the potential for autonomous vehicles to revolutionize mining safety is immense, the challenges of technical limitations, infrastructure needs, regulatory compliance, and workforce acceptance must be addressed. By tackling these issues head-on, the mining industry can pave the way for a safer and more efficient future.

- What are the main benefits of using autonomous vehicles in mining?

Autonomous vehicles can significantly enhance safety by reducing human exposure to hazardous environments, improve operational efficiency, and lower costs associated with labor and accidents. - How do autonomous vehicles navigate in challenging mining environments?

These vehicles use advanced sensors, cameras, and AI algorithms to detect and respond to their surroundings, allowing them to navigate safely in unpredictable conditions. - What kind of training is required for workers to adapt to autonomous vehicles?

Workers may need training on how to operate and interact with autonomous systems, including understanding the technology's capabilities and limitations. - Are there any legal concerns regarding the use of autonomous vehicles in mining?

Yes, there are regulatory challenges and liability issues that companies must navigate, including ensuring compliance with safety standards and addressing potential accidents involving autonomous vehicles.

Drones in Mining Operations

Drones are revolutionizing the mining industry by providing innovative solutions for surveying, monitoring, and inspection tasks. Imagine a bird's-eye view of a vast mining site, where every nook and cranny can be assessed without putting human lives at risk. These unmanned aerial vehicles (UAVs) are equipped with advanced cameras and sensors, enabling them to collect crucial data that was once difficult to obtain. The integration of drones into mining operations not only enhances safety but also boosts efficiency, making them indispensable tools in modern mining.

One of the most significant advantages of using drones in mining is their ability to perform real-time monitoring. With the capability to fly over large areas quickly, drones can identify potential hazards, such as landslides or equipment failures, before they escalate into serious problems. This proactive approach to safety can save lives and prevent costly downtime. Furthermore, drones can map out terrain and create detailed topographical maps, which are essential for planning and operational efficiency.

The use of drones also extends to environmental monitoring. Mining operations can have a significant impact on the surrounding ecosystem, and drones help mitigate this by monitoring air quality, vegetation health, and water sources. By collecting data from hard-to-reach areas, drones provide insights that can lead to better environmental management practices. This not only helps in compliance with regulations but also enhances the company's reputation as a socially responsible entity.

Additionally, drones can assist in inventory management. By utilizing aerial imagery, mining companies can keep track of stockpiles and materials more accurately than traditional methods. This reduces the chances of overestimating or underestimating available resources, which can lead to financial losses. The efficiency gained from drone technology can translate into significant cost savings and improved operational workflows.

However, while the benefits of drones in mining operations are clear, there are also challenges to consider. Regulatory compliance is one of the primary hurdles; mining companies must ensure that they adhere to local laws governing drone usage. Moreover, the initial investment in drone technology and training personnel to operate these devices can be substantial. Yet, the long-term advantages often outweigh these initial costs, making drones a worthwhile investment for mining companies focused on safety and efficiency.

In conclusion, the integration of drones in mining operations represents a significant leap forward in enhancing safety and operational efficiency. As technology continues to advance, we can expect drones to become even more sophisticated, offering new capabilities that further improve the mining industry's safety standards.

- What types of drones are used in mining?

Mining operations typically use fixed-wing drones for large area coverage and multi-rotor drones for detailed inspections and surveys.

- How do drones improve safety in mining?

Drones provide real-time data and monitoring, allowing for the early detection of hazards and reducing the need for personnel to enter dangerous areas.

- Are there regulations for using drones in mining?

Yes, mining companies must comply with local aviation regulations, which may include obtaining permits and adhering to flight restrictions.

- Can drones be used for environmental monitoring?

Absolutely! Drones are excellent for monitoring air quality, vegetation, and water sources, helping companies maintain compliance with environmental regulations.

Robotics for Hazardous Environment Operations

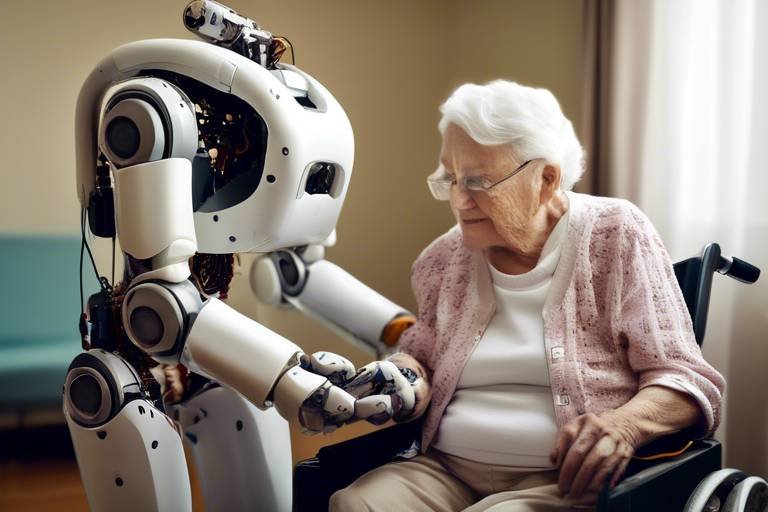

In the mining industry, safety is paramount, especially when it comes to operations in hazardous environments. This is where robotics shines, acting as a shield between human workers and the potential dangers lurking underground or in remote locations. The integration of robotic technology into hazardous operations is not just a trend; it's a revolution that is reshaping how mining companies approach safety. Imagine sending a robot into a perilous situation rather than risking a human life. This shift not only enhances worker protection but also improves operational efficiency.

Robots are designed to perform various tasks in environments that are often too dangerous for human workers. For instance, in areas where toxic gases or unstable ground conditions exist, robots can be deployed to collect data, inspect equipment, or even carry out repairs. This capability significantly reduces the risk of accidents and injuries. The use of robotics in these scenarios is akin to having a highly skilled worker who can operate in extreme conditions without the fear of personal harm.

One of the most impressive applications of robotics in hazardous environments is remote monitoring and inspection. Traditional methods of inspecting mining sites often require workers to enter dangerous zones, exposing them to various risks. However, with advancements in robotic technology, companies can now utilize drones and other remote-controlled devices to conduct inspections safely. These robots can gather real-time data, providing insights into the condition of equipment and the environment without putting human lives at risk.

Moreover, emergency response robots have emerged as a critical component of mining safety protocols. In the event of an accident, these robots can quickly navigate hazardous areas to assess damage, locate trapped workers, and even deliver supplies. Their ability to operate in dangerous conditions means that rescue operations can commence much sooner, potentially saving lives. The speed and efficiency of these robots can be the difference between life and death in emergency situations.

To illustrate the impact of robotics on hazardous mining operations, consider the following table that outlines the key benefits and applications:

| Application | Benefits |

|---|---|

| Remote Monitoring | Real-time data collection, reduced risk for workers, enhanced decision-making |

| Inspection Drones | Access to hard-to-reach areas, improved safety, faster inspections |

| Emergency Response Robots | Quick assessment of hazards, life-saving capabilities, efficient rescue operations |

As we continue to embrace these technological advancements, the mining industry is not only improving safety standards but also setting a precedent for other industries to follow. The future looks promising, with robotics paving the way for safer operations in hazardous environments. The question remains, how far can we push the boundaries of technology to ensure the safety of workers in even the most dangerous conditions? Only time will tell, but one thing is clear: robotics is here to stay, and it’s transforming the mining landscape for the better.

- What types of robots are used in hazardous mining operations?

Various types of robots, including drones for aerial inspections and ground-based robots for remote monitoring, are employed to enhance safety in hazardous environments. - How do emergency response robots function during mining accidents?

Emergency response robots are equipped with sensors and cameras that allow them to assess dangerous situations, locate trapped individuals, and deliver necessary supplies, all while minimizing risks to human rescuers. - Can robotics completely eliminate risks in mining?

While robotics significantly reduce risks, they cannot completely eliminate them. However, they enhance safety protocols and provide invaluable support in hazardous situations.

Remote Monitoring and Inspection

In the ever-evolving landscape of mining, technologies are emerging as game-changers. Imagine being able to oversee vast mining operations from the comfort of a control room, far removed from the dust and danger of the mines. This is not just a futuristic dream; it’s a reality made possible by advanced robotics and sensor technologies. These innovations allow for the collection of real-time data, enabling operators to make informed decisions that significantly enhance safety.

One of the standout features of remote monitoring is its ability to provide continuous surveillance of mining sites. With the integration of high-definition cameras and thermal imaging technologies, operators can detect potential hazards before they escalate into serious incidents. For instance, if a section of the mine shows signs of instability, alerts can be triggered automatically, prompting immediate action to mitigate risks. This proactive approach not only protects workers but also minimizes downtime and operational costs.

Moreover, remote inspection drones are gaining traction in the mining industry. These unmanned aerial vehicles (UAVs) can access hard-to-reach areas, performing inspections that would be perilous for human workers. Equipped with various sensors and imaging technologies, drones can gather critical data on structural integrity, equipment conditions, and environmental impacts. The benefits of using drones include:

- Increased Safety: Drones can operate in hazardous environments, reducing the need for human presence in dangerous areas.

- Cost-Effectiveness: By minimizing the need for scaffolding and other safety measures, drones can significantly cut inspection costs.

- Efficiency: Drones can cover large areas quickly, providing timely data that helps in decision-making.

Furthermore, the data gathered through remote monitoring can be analyzed using machine learning algorithms to predict equipment failures before they occur. This predictive maintenance approach not only enhances safety but also optimizes the overall efficiency of mining operations. By addressing potential issues early, companies can avoid costly repairs and ensure that their operations run smoothly.

As we look to the future, the role of remote monitoring and inspection in mining safety will only grow. The integration of artificial intelligence and big data analytics will further refine these technologies, making them even more effective in identifying risks and improving safety protocols. In a field where every second counts, the ability to monitor operations in real-time can mean the difference between safety and disaster.

Q1: How does remote monitoring enhance safety in mining?

A1: Remote monitoring enhances safety by providing real-time data on site conditions, allowing for quick identification of hazards and reducing the need for personnel in dangerous areas.

Q2: What technologies are used in remote monitoring?

A2: Technologies used include high-definition cameras, thermal imaging, and drones equipped with various sensors for detailed inspections.

Q3: Can remote monitoring reduce operational costs?

A3: Yes, by minimizing downtime and preventing equipment failures through predictive maintenance, remote monitoring can significantly reduce operational costs.

Q4: What is the future of remote monitoring in mining?

A4: The future includes advancements in AI and big data analytics, which will enhance the effectiveness of remote monitoring technologies and improve safety protocols.

Emergency Response Robots

In the unpredictable world of mining, where danger can lurk around every corner, emerge as unsung heroes. These remarkable machines are specifically designed to tackle hazardous situations that would otherwise put human lives at risk. Imagine a scenario where a mining accident occurs—traditional rescue methods could take precious time, but with the deployment of these robots, the response can be swift and efficient. Equipped with advanced sensors and communication systems, these robots can navigate treacherous terrains and provide crucial support in emergencies.

One of the standout features of emergency response robots is their ability to operate in environments that are deemed unsafe for humans. For instance, in the aftermath of a collapse or explosion, these robots can enter the site to assess damage, locate trapped miners, and even deliver supplies such as water or medical kits. This capability not only enhances the safety of rescue operations but also significantly increases the chances of survival for those in distress.

Moreover, the integration of artificial intelligence (AI) into these robots allows them to analyze situations in real-time. They can identify potential hazards, such as gas leaks or unstable structures, and relay this information back to human operators. This data-driven approach ensures that rescue teams can make informed decisions quickly, ultimately saving lives. As we delve deeper into the capabilities of these robots, it's essential to understand the technology behind them.

Emergency response robots come in various forms, each tailored to specific tasks. Here’s a brief overview of some types:

| Type of Robot | Function |

|---|---|

| Search and Rescue Robots | Designed to locate and assist trapped individuals. |

| Inspection Robots | Assess structural integrity and identify hazardous conditions. |

| Supply Delivery Robots | Transport essential supplies to isolated workers. |

However, the journey of integrating these robots into mining operations is not without its challenges. Training personnel to work alongside these machines, ensuring seamless communication, and addressing technical malfunctions are just a few hurdles that the industry faces. Nevertheless, the benefits far outweigh the challenges, and the continued development of emergency response robots is paving the way for a safer mining environment.

As we look to the future, it’s clear that emergency response robots will play an increasingly vital role in mining safety. With advancements in technology, such as improved battery life and enhanced mobility, these robots will become even more effective in crisis situations. The mining industry is on the brink of a revolution where human safety is prioritized, and emergency response robots stand at the forefront of this change.

The Future of Robotics in Mining Safety

The future of robotics in mining safety is not just a vision; it's a rapidly approaching reality that promises to revolutionize the industry. As technology continues to evolve, we can expect significant advancements that will further enhance safety protocols, efficiency, and the overall working environment for miners. Imagine a world where robots not only take on the most dangerous tasks but also provide real-time data analytics, ensuring that human workers are always protected from potential hazards.

One of the most exciting prospects is the integration of artificial intelligence (AI) with mining robotics. This combination will enable machines to learn from their environments, making them more autonomous and capable of adapting to unforeseen circumstances. For instance, AI could allow drones to identify structural weaknesses in mines or detect gas leaks, alerting workers before a disaster strikes. The potential for predictive maintenance will also be a game-changer, as robots can monitor equipment health and predict failures before they occur, thus preventing accidents.

Moreover, the use of collaborative robots, or cobots, is set to increase. These robots are designed to work alongside humans, enhancing safety by taking over the most hazardous tasks. In this scenario, human workers can focus on more complex decision-making processes while leaving repetitive or dangerous work to their robotic counterparts. This synergy not only improves safety but also boosts productivity, as tasks are completed more efficiently.

As we look towards the future, we must also consider the regulatory landscape. With the rise of robotics in mining, regulatory bodies will need to adapt and create guidelines that ensure the safe integration of these technologies. This could include standards for robot operation, maintenance, and emergency protocols. The mining industry will need to collaborate closely with regulators to establish these frameworks, ensuring that safety remains the top priority.

To give you a clearer picture, let’s look at some potential advancements in mining robotics:

| Advancement | Description |

|---|---|

| AI Integration | Robots will use AI to learn from their environments and make real-time decisions. |

| Predictive Maintenance | Robots will monitor equipment health to predict and prevent failures. |

| Collaborative Robots (Cobots) | These robots will work alongside humans, handling dangerous tasks. |

| Advanced Sensors | Robots will be equipped with sensors to detect environmental hazards. |

In conclusion, the future of robotics in mining safety holds immense promise. As we continue to embrace these technologies, we can expect a safer, more efficient mining industry that not only protects workers but also enhances productivity. The road ahead is filled with opportunities, and the collaboration between humans and robots will pave the way for a new era in mining.

- What are the main benefits of using robotics in mining? Robotics enhances safety, reduces operational costs, and increases productivity by performing hazardous tasks.

- How does AI improve mining robotics? AI allows robots to learn from their environments, adapt to situations, and make real-time decisions, enhancing their effectiveness.

- What challenges do we face in implementing robotics in mining? Challenges include technical limitations, the need for regulatory compliance, and the initial costs of investment.

- Will robots replace human workers in mining? While robots will take on dangerous tasks, human oversight and decision-making will remain crucial in mining operations.

Frequently Asked Questions

- What role do robotics play in enhancing mining safety?

Robotics significantly enhance mining safety by automating hazardous tasks, reducing the need for human workers in dangerous environments. This includes using autonomous vehicles to transport materials and drones for surveying, which minimizes human exposure to risks.

- What types of robots are commonly used in mining operations?

In mining, several types of robots are utilized, including autonomous vehicles for material transport, drones for aerial inspections, and specialized robots designed for remote monitoring and emergency responses. Each type serves a unique purpose in improving safety and efficiency.

- How do autonomous vehicles improve safety in mining?

Autonomous vehicles enhance safety by operating in hazardous conditions without human intervention. They are designed to navigate through difficult terrains, transporting materials while reducing the risk of accidents and injuries associated with human-operated vehicles.

- What challenges are associated with implementing robotics in mining?

Implementing robotics in mining comes with challenges such as technical limitations, high initial costs, and the need for regulatory compliance. Overcoming these obstacles requires careful planning, investment in technology, and collaboration with regulatory bodies.

- How do drones contribute to mining safety?

Drones contribute to mining safety by providing real-time data collection and aerial surveillance. They can inspect dangerous areas without putting human workers at risk, allowing for better monitoring of conditions and quicker responses to potential hazards.

- What is the significance of remote monitoring in mining?

Remote monitoring is crucial in mining as it allows for continuous observation of operations and immediate detection of hazards. This technology enables quick decision-making and enhances safety by minimizing the need for personnel to enter dangerous areas.

- What are emergency response robots and how do they function?

Emergency response robots are designed to assist in crisis situations, such as mine collapses or hazardous material spills. They can perform search and rescue operations, assess damage, and provide critical data to human responders, thus improving overall safety during emergencies.

- What does the future hold for robotics in mining safety?

The future of robotics in mining safety looks promising, with advancements in AI, machine learning, and sensor technologies expected to lead to even safer and more efficient operations. Innovations will likely continue to reduce risks for human workers while enhancing productivity.