How Robotics is Enhancing Hazardous Waste Management

In today's world, where environmental concerns are at the forefront of global discussions, the role of robotics in hazardous waste management is nothing short of revolutionary. Robotics technology is not just a futuristic concept; it is actively reshaping how we handle dangerous materials, ensuring that safety and efficiency are prioritized. Imagine a world where hazardous waste can be managed with minimal human intervention, reducing the risk of exposure to toxic substances. This is not just a dream—it's happening now!

As we dive into the details, it's essential to understand that robotics encompasses a wide range of technologies, from automated vehicles to advanced robotic arms. These innovations are designed to tackle the complexities of hazardous waste management, which traditionally involves significant risks for workers. By integrating robotics into this field, we are not only enhancing operational capabilities but also paving the way for a safer and more efficient waste management system.

In this article, we'll explore how robotics is transforming hazardous waste management, highlighting the advancements and applications that are making a real difference. We'll also delve into the future potential of these technologies, examining how they can continue to improve safety and efficiency in handling dangerous materials. So, buckle up as we take a closer look at the fascinating intersection of robotics and waste management!

Introduction to Robotics in Waste Management

In today's rapidly evolving world, the integration of robotics technology into various sectors has become a game-changer, and waste management is no exception. Imagine a scenario where hazardous materials are handled with precision and care, minimizing risks to human workers. This is not just a dream but a reality that robotics is making possible. Robotics in waste management is not merely about machines replacing humans; it's about enhancing operational efficiency and safety. The significance of robotics in this industry cannot be overstated, as it addresses the growing need for effective solutions to manage hazardous waste.

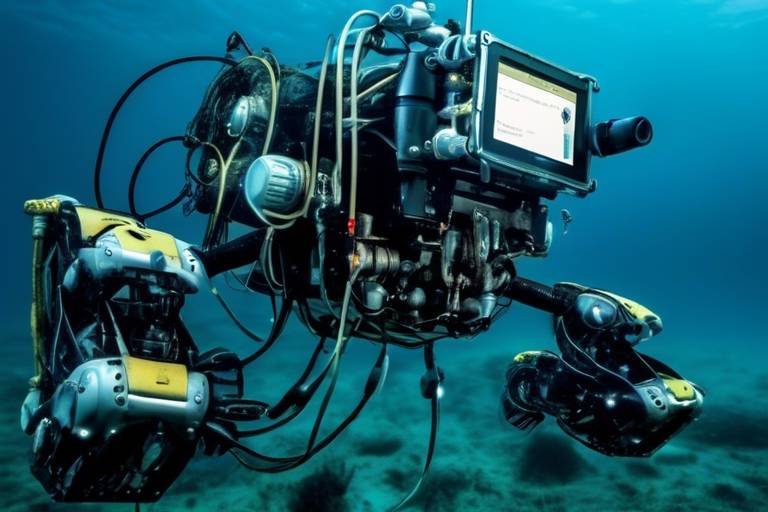

So, what exactly does it mean for robots to play a role in waste management? At its core, robotics in this field involves the use of automated systems to handle, sort, and process waste materials that pose significant risks to human health and the environment. These systems can range from autonomous vehicles that navigate waste facilities to robotic arms designed to safely manipulate dangerous substances. The beauty of these technologies lies in their ability to operate in environments that are often too hazardous for humans, thereby reducing the likelihood of accidents and exposure to toxic elements.

Moreover, the implementation of robotics comes with a plethora of benefits. For instance, it can lead to improved accuracy in sorting recyclable materials, which is crucial for effective waste management. By utilizing advanced sensors and AI algorithms, robots can distinguish between different types of waste with remarkable precision. This not only enhances recycling rates but also contributes to a more sustainable future.

As we delve deeper into the world of robotics in hazardous waste management, it's essential to recognize that this technology is still in its infancy. The potential for growth and innovation is enormous. With advancements in artificial intelligence and machine learning, we can expect to see robots that are not only more efficient but also capable of learning from their environments and adapting to new challenges. This adaptability is crucial, especially in the ever-changing landscape of waste management.

In conclusion, the introduction of robotics into waste management is a significant step forward in addressing the challenges posed by hazardous materials. It opens up a world of possibilities for safer, more efficient, and environmentally friendly waste handling processes. As we continue to explore this exciting frontier, it’s clear that robotics will play a pivotal role in shaping the future of waste management.

Types of Robots Used in Hazardous Waste Management

When it comes to tackling the challenges of hazardous waste management, robotics offers a diverse array of solutions tailored to meet specific needs. These robots are not just fancy gadgets; they are powerful tools designed to enhance safety and efficiency in environments that pose significant risks to human workers. Let's dive into some of the most common types of robots used in this critical field.

One prominent category is autonomous vehicles. These robots are equipped with advanced navigation systems that allow them to operate without human intervention. Imagine a vehicle that can navigate through a waste facility, collecting and transporting hazardous materials to designated areas without putting anyone in harm's way. Autonomous vehicles are particularly useful in large-scale operations where human presence is limited due to safety concerns. They can be programmed to follow specific routes, ensuring that hazardous materials are handled swiftly and safely.

Another essential type of robot is the robotic arm. Think of this as the mechanical equivalent of a human arm, capable of performing intricate tasks with precision. Robotic arms can be used for various applications, such as sorting, packaging, and even dismantling hazardous waste. These machines can be outfitted with specialized tools that allow them to manipulate materials that are either too dangerous or too toxic for human workers to handle. For instance, a robotic arm can safely pick up and dispose of chemical containers, reducing the risk of spills or exposure.

In addition to these, drone technology is making waves in the hazardous waste management sector. Drones can survey large areas quickly, providing real-time data about waste conditions and identifying potential hazards. They can be equipped with cameras and sensors that detect chemical leaks or monitor waste levels in hard-to-reach places. By using drones, companies can gain valuable insights without risking employee safety, making them an invaluable asset in hazardous waste management.

Moreover, there are collaborative robots, or cobots, which are designed to work alongside human operators. These robots are equipped with sensors that allow them to detect human presence and adjust their movements accordingly. This collaborative approach can enhance productivity while ensuring a safer working environment. For example, a cobot can assist workers in lifting heavy containers of hazardous waste, reducing the physical strain on employees while maintaining safety protocols.

To summarize, the types of robots employed in hazardous waste management are as varied as the challenges they address. From autonomous vehicles and robotic arms to drones and collaborative robots, each type plays a vital role in enhancing safety and efficiency. As technology continues to evolve, we can expect even more innovative robotic solutions to emerge, paving the way for a safer and more effective approach to managing hazardous waste.

- What are the main benefits of using robots in hazardous waste management? Robots help reduce human exposure to dangerous materials, improve efficiency in waste processing, and enhance overall safety in hazardous environments.

- How do autonomous vehicles navigate in waste management facilities? Autonomous vehicles use advanced sensors and GPS technology to navigate predetermined routes while avoiding obstacles.

- Can robotic arms handle all types of hazardous materials? Robotic arms can be equipped with specialized tools to handle various hazardous materials, but specific configurations may be required for different substances.

- What role do drones play in hazardous waste management? Drones are used for surveying areas, monitoring waste conditions, and detecting potential hazards, providing valuable data without risking human safety.

Safety Improvements Through Robotics

When it comes to managing hazardous waste, safety is not just a priority; it’s a necessity. Traditional methods of handling dangerous materials often put workers at significant risk. However, the advent of robotics in this field has ushered in a new era of safety improvements that are nothing short of revolutionary. Imagine a world where hazardous materials are handled by machines, allowing human workers to maintain a safe distance. This is not just a dream—it's the reality that robotics is creating.

One of the most compelling benefits of robotic systems in hazardous waste management is their ability to minimize human exposure to dangerous substances. For instance, robots equipped with advanced sensors and cameras can identify and analyze hazardous materials without any human intervention. This capability allows for a thorough assessment of waste without putting anyone in harm's way. Think of it as sending in a highly trained scout to gather intel before the real team moves in.

Additionally, robotics can perform tasks that are inherently risky for humans. For example, robotic arms can be used to lift and transport heavy containers of toxic waste, significantly reducing the physical strain and risk of injury for workers. This not only enhances safety but also increases the efficiency of waste handling operations. The table below highlights some of the key safety improvements brought about by robotics:

| Safety Improvement | Description |

|---|---|

| Reduced Human Exposure | Robots handle hazardous materials, minimizing the risk to human workers. |

| Automated Monitoring | Robotic systems can continuously monitor hazardous environments, alerting personnel to dangers. |

| Precision Handling | Robots can perform tasks with high precision, reducing the chances of accidents. |

| Remote Operation | Many robotic systems can be operated remotely, keeping human operators at a safe distance. |

Moreover, robots can be programmed to follow strict safety protocols, ensuring that every action taken is calculated and deliberate. This level of control reduces the likelihood of human error, which is often a significant factor in workplace accidents. By integrating robotics into hazardous waste management, companies are not only enhancing safety but are also fostering a culture of responsibility and care for their workers.

In summary, the integration of robotics in hazardous waste management is proving to be a game-changer for safety. With robots taking on the most dangerous tasks, human workers can focus on oversight and decision-making roles, which are crucial for a safe and effective waste management process. As we look to the future, the continued development of robotic technologies promises even greater safety enhancements, paving the way for a more secure working environment in this critical industry.

- How do robots reduce human exposure to hazardous materials? Robots can be designed to handle, transport, and analyze hazardous materials without human intervention, significantly minimizing the risk to workers.

- What types of tasks can robots perform in hazardous waste management? Robots can lift heavy containers, monitor environments, and perform precise handling tasks, all while following strict safety protocols.

- Are there any risks associated with using robots in hazardous waste management? While robots improve safety, there are still risks related to mechanical failures and the need for proper training for human operators.

Efficiency Gains in Waste Processing

The integration of robotics in hazardous waste management has ushered in a new era of efficiency that was once thought to be unattainable. Imagine a world where dangerous materials are handled with precision and speed, significantly reducing the time it takes to process hazardous waste. This is not just a dream; it's a reality that robotic systems are making possible. By automating various tasks, these robots are transforming the way waste facilities operate, leading to faster processing times and improved throughput.

One of the most remarkable aspects of robotic systems is their ability to work tirelessly without the fatigue that human workers might experience. This means that while humans may need breaks, robots can continue to operate, processing waste around the clock. For instance, robotic arms can efficiently sort and package hazardous materials, ensuring that they are handled correctly and safely. The precision of these robots minimizes the chances of errors, which can be catastrophic in hazardous waste management.

Moreover, the implementation of autonomous vehicles within waste processing facilities has revolutionized logistics. These vehicles can transport hazardous materials from one location to another without human intervention. This not only speeds up the entire process but also significantly reduces the risk of accidents. Consider the following table that illustrates the efficiency gains realized through the use of robotics:

| Task | Traditional Method Time (hours) | Robotic Method Time (hours) | Efficiency Gain (%) |

|---|---|---|---|

| Sorting Waste | 10 | 4 | 60% |

| Transporting Materials | 8 | 2 | 75% |

| Packaging | 6 | 3 | 50% |

As shown in the table, the efficiency gains from robotic systems can be staggering. Tasks that once took hours can now be completed in a fraction of the time, offering facilities the ability to process more waste without compromising safety. Additionally, the data collected by robotic systems can be analyzed to optimize operations further, allowing facilities to continually improve their processes over time.

Furthermore, the integration of robotics also allows for better resource allocation. With robots handling repetitive and hazardous tasks, human workers can focus on more complex and strategic roles within the facility. This not only enhances job satisfaction but also leads to a more skilled workforce, ultimately benefiting the entire operation.

In summary, the efficiency gains achieved through the use of robotics in hazardous waste processing are profound. By automating tasks, minimizing errors, and allowing for continuous operation, robotic systems are setting a new standard in the industry. The future of waste management looks not only safer but also significantly more efficient, paving the way for a cleaner and more sustainable environment.

- How do robots improve safety in hazardous waste management? Robots minimize human exposure to dangerous materials, reducing the risk of accidents and health hazards.

- What types of tasks can robots perform in waste processing? Robots can sort, package, and transport hazardous materials, among other tasks, enhancing overall efficiency.

- Are there any downsides to using robotics in waste management? Yes, challenges such as high initial costs and the need for specialized training can hinder implementation.

- What is the future of robotics in waste management? The future looks promising with advancements in AI and machine learning, which will further enhance the capabilities of robotic systems.

Case Studies of Robotics in Action

As we delve into the real-world applications of robotics in hazardous waste management, it's fascinating to see how these technologies have been implemented to tackle some of the toughest challenges in the industry. One notable example comes from the Hanford Site in Washington State, which is home to some of the most dangerous radioactive waste in the United States. Here, robotic systems have been deployed to assist in the retrieval and processing of this waste. The use of teleoperated robots allows workers to control machines from a safe distance, significantly reducing their exposure to hazardous materials. These robots are equipped with advanced sensors and cameras, providing operators with real-time data to make informed decisions.

Another compelling case is the U.S. Department of Energy's use of autonomous drones for site inspections. These drones are capable of navigating complex environments, conducting aerial surveys, and identifying potential contamination areas without putting human lives at risk. The efficiency gained through these robotic inspections has led to quicker responses to potential hazards, which is crucial in maintaining safety standards.

Furthermore, at a waste processing facility in Germany, robotic arms have been integrated into the sorting process. These robotic systems utilize machine learning algorithms to identify and separate hazardous materials from regular waste. The precision of these robots not only enhances the sorting accuracy but also speeds up the entire process, allowing for a greater volume of waste to be processed in a shorter amount of time. A recent study showed that the facility increased its throughput by 30% after implementing these robotic systems.

To illustrate the impact of these robotic solutions, consider the following table summarizing key benefits observed in these case studies:

| Case Study | Location | Robotic Technology Used | Key Benefits |

|---|---|---|---|

| Hanford Site | Washington, USA | Teleoperated Robots | Reduced human exposure, real-time data collection |

| U.S. Department of Energy | Various Locations | Autonomous Drones | Efficient site inspections, quicker hazard responses |

| Waste Processing Facility | Germany | Robotic Arms with AI | Increased sorting accuracy, 30% throughput improvement |

These case studies not only highlight the practical applications of robotics but also underscore the potential for innovation in hazardous waste management. As technology continues to evolve, we can expect even more groundbreaking solutions that will further enhance safety and efficiency in this critical field.

- What types of robots are commonly used in hazardous waste management?

Common types include teleoperated robots, autonomous drones, and robotic arms equipped with AI for sorting and processing waste.

- How do robots improve safety in hazardous waste management?

Robots minimize human exposure to dangerous materials, allowing for remote operation and reducing the risk of accidents.

- What are some challenges in implementing robotics in this field?

Challenges include high initial costs, technical limitations, and the requirement for specialized training for operators.

Challenges in Implementing Robotics

While the integration of robotics into hazardous waste management offers a plethora of benefits, it's not without its challenges. One of the major hurdles is the high initial costs associated with purchasing and installing robotic systems. These advanced technologies often require significant capital investment, which can be a daunting prospect for many waste management facilities, especially smaller operations that may already be operating on tight budgets.

Another challenge lies in the technical limitations of current robotic systems. Although robots have made remarkable strides in terms of functionality, they still face difficulties in navigating complex environments filled with unpredictable hazards. For example, a robotic arm designed to handle toxic materials might struggle with irregularly shaped waste or varying material densities, potentially leading to inefficiencies or even accidents.

Moreover, the successful implementation of robotics requires a workforce that is not only skilled in operating these machines but also knowledgeable about the specific challenges posed by hazardous waste. This leads to the necessity for specialized training, which can be time-consuming and costly. Facilities must invest in training programs to ensure that their employees can effectively work alongside robotic systems, understand their limitations, and troubleshoot any issues that arise.

Additionally, integrating robotics into existing workflows can be a complex process. Organizations may face resistance from employees who are concerned about job security or who may feel overwhelmed by the new technology. This cultural shift within an organization can be challenging to navigate, requiring effective communication and change management strategies to ensure that all staff members are on board with the transition.

Finally, there are also regulatory hurdles that must be addressed. The waste management industry is heavily regulated, and any new technology must comply with existing laws and standards. This can slow down the adoption of robotics, as companies must ensure that their robotic systems meet all necessary safety and environmental regulations before they can be deployed.

In summary, while the potential for robotics to revolutionize hazardous waste management is immense, the challenges of implementation cannot be overlooked. Addressing these obstacles will require a concerted effort from industry stakeholders to invest in technology, training, and regulatory compliance, paving the way for a safer and more efficient future in waste management.

- What are the main benefits of using robotics in hazardous waste management? Robotics can enhance safety, improve efficiency, and reduce human exposure to dangerous materials.

- What types of robots are commonly used in hazardous waste management? Common types include autonomous vehicles for transportation and robotic arms for handling and sorting waste.

- How can facilities overcome the challenges of implementing robotics? Facilities can invest in training, seek partnerships for technology acquisition, and develop a change management strategy to ease the transition.

- Are there any regulatory concerns with robotic systems in waste management? Yes, robotic systems must comply with existing safety and environmental regulations, which can complicate their deployment.

Future Trends in Robotic Waste Management

The world of hazardous waste management is on the brink of a technological revolution, and robotics is at the forefront of this change. As we look toward the future, several trends are emerging that promise to reshape how we handle hazardous materials. One of the most exciting developments is the integration of artificial intelligence (AI) with robotic systems. This combination allows robots to not only perform repetitive tasks but also to learn from their environments, making them more adaptable and efficient. Imagine a robot that can assess the toxicity of waste materials in real time, adjusting its methods accordingly. This capability could drastically reduce the risks associated with human error in waste management.

Another significant trend is the rise of collaborative robots, or cobots, which are designed to work alongside human operators. These robots enhance safety and efficiency by taking on the most dangerous tasks while allowing human workers to focus on oversight and decision-making. For instance, a cobot might be responsible for transporting hazardous materials, while a human monitors the process and intervenes when necessary. This synergy not only maximizes productivity but also fosters a safer working environment.

Moreover, the use of drone technology is gaining traction in hazardous waste management. Drones equipped with advanced sensors can conduct aerial surveys of waste sites, identifying potential hazards and monitoring environmental conditions without putting human lives at risk. This capability is particularly valuable in remote or hard-to-reach areas where traditional methods may be impractical. The data collected by drones can be analyzed to inform better waste management strategies, leading to more effective interventions.

As we embrace these advancements, it’s essential to consider the role of machine learning. This technology allows robots to process large amounts of data and make informed decisions based on past experiences. For instance, a robotic system could analyze historical waste processing data to optimize current operations, leading to reduced costs and improved safety outcomes. The potential for machine learning to enhance predictive maintenance and operational efficiency is enormous, paving the way for smarter waste management solutions.

Finally, the future of robotic waste management is also about sustainability. As environmental concerns grow, there is an increasing demand for technologies that can not only manage waste but also help in recycling and recovery efforts. Robotics can play a pivotal role in sorting recyclable materials from hazardous waste, ensuring that valuable resources are not lost. By integrating robotics into recycling processes, we can create a more circular economy that minimizes waste and maximizes resource recovery.

In summary, the future trends in robotic waste management are not just about technology; they are about creating a safer, more efficient, and sustainable approach to handling hazardous materials. As these technologies continue to evolve, we can expect to see significant improvements in how we manage waste, ultimately leading to a cleaner and safer environment for all.

- What types of robots are used in hazardous waste management? Various types of robots, including autonomous vehicles, robotic arms, and drones, are utilized to enhance safety and efficiency in waste management.

- How does AI improve robotic waste management? AI enables robots to learn from their environments and make real-time decisions, reducing human error and increasing operational efficiency.

- What are collaborative robots (cobots)? Cobots are designed to work alongside human workers, taking on dangerous tasks while allowing humans to focus on supervision and decision-making.

- How can drones be beneficial in waste management? Drones can conduct aerial surveys, monitor environmental conditions, and identify hazards without risking human lives, especially in remote areas.

- What role does machine learning play in waste management? Machine learning helps robots analyze data and optimize operations based on past experiences, improving efficiency and reducing costs.

Conclusion: The Path Forward

In conclusion, the integration of robotics into hazardous waste management is not just a trend; it represents a monumental shift towards a safer, more efficient future. As we have explored throughout this article, the advancements in robotic technology are paving the way for innovative solutions that significantly enhance the handling of dangerous materials. The potential of robotics to minimize human exposure to hazardous environments cannot be overstated. By reducing risks associated with manual handling, we are not only protecting workers but also ensuring that hazardous waste is managed more effectively.

Moreover, the efficiency gains that come from robotic systems are impressive. With the ability to streamline operations and reduce processing times, robotics enables waste management facilities to enhance their throughput, ultimately leading to better resource utilization. This is crucial as we face increasing amounts of waste and the ongoing challenge of managing it responsibly.

However, as we look to the future, it is essential to acknowledge the challenges that lie ahead. The initial costs of implementing robotic systems can be high, and there is a pressing need for specialized training to ensure that personnel can operate and maintain these advanced technologies effectively. Addressing these obstacles will be key to fully realizing the benefits of robotics in this sector.

As we move forward, the future trends in robotic waste management are promising. With emerging technologies such as artificial intelligence and machine learning, we can expect even greater advancements that will further enhance safety and efficiency. The path ahead is not just about adopting new technologies; it’s about fostering a culture of innovation and investment in robotic solutions that can transform hazardous waste management for the better.

Ultimately, the commitment to embracing robotics in this field is a commitment to a safer, cleaner environment. By investing in these technologies today, we are not only addressing the challenges of hazardous waste management but also setting the stage for a sustainable future.

- What types of robots are commonly used in hazardous waste management?

Common types include autonomous vehicles for transport and robotic arms for handling materials.

- How do robots improve safety in hazardous waste management?

Robots minimize human exposure to dangerous materials, thereby reducing the risk of accidents and health hazards.

- What challenges do companies face when implementing robotic systems?

Challenges include high initial costs, technical limitations, and the need for specialized training for personnel.

- What is the future of robotics in waste management?

The future looks bright with advancements in AI and machine learning, which can enhance the capabilities of robotic systems.

Frequently Asked Questions

- What role do robots play in hazardous waste management?

Robots are revolutionizing hazardous waste management by automating the handling of dangerous materials. They can perform tasks that are too risky for humans, such as sorting, transporting, and processing hazardous waste, thereby enhancing both safety and efficiency.

- What types of robots are commonly used in this field?

There are several types of robots utilized in hazardous waste management, including autonomous vehicles for transporting waste and robotic arms for sorting and manipulating materials. Each type is designed to address specific challenges in waste handling, making operations smoother and safer.

- How do robots improve safety for workers?

By taking over dangerous tasks, robots significantly reduce human exposure to hazardous materials. This minimizes the risk of accidents and health issues, creating a safer work environment for everyone involved in waste management operations.

- Can robotics increase efficiency in waste processing?

Absolutely! Robotics streamline operations, reduce processing times, and enhance throughput. By automating repetitive tasks, robots enable waste facilities to operate more efficiently, leading to faster processing and better resource management.

- Are there any real-world examples of robotics in action?

Yes, there are numerous case studies showcasing successful robotic implementations in hazardous waste management. These examples highlight how innovative robotic solutions have positively impacted waste handling processes, demonstrating their effectiveness and reliability.

- What challenges are faced when implementing robotics?

While the benefits are clear, challenges such as high initial costs, technical limitations, and the need for specialized training can hinder the adoption of robotics in hazardous waste management. Addressing these issues is crucial for successful implementation.

- What does the future hold for robotics in waste management?

The future looks promising, with advancements in AI and machine learning poised to enhance robotic capabilities. These technologies will likely lead to even more efficient and effective solutions for hazardous waste management, paving the way for a safer and more sustainable future.